+ 90 535 334 61 94

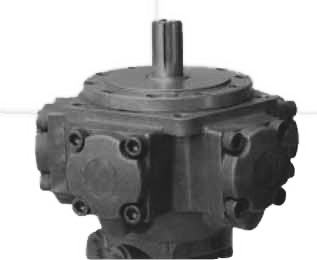

Pump Hydraulic Maintenance Repair

MGA SHIPPING

Pump Hydraulic Maintenance Repair

Pumps are important equipment used to move liquid or gas from one place to another. In order for the pumps to work properly, maintenance and repair operations must be carried out at certain periods. Here is some information about pump maintenance and repair:some information about maintenance and repair:

Maintenance of Pumps

Cleaning and Lubrication: Cleaning and lubrication must be done to ensure proper pump operation. Dirty parts and insufficient lubrication can adversely affect the performance of pumps.

Replacement of Gaskets:The pump's seals ensure sealing. It is important to replace gaskets regularly as they wear out over time.

Control of Bearings: Pump bearings reduce friction between moving parts. Bearings should be checked to ensure they are working properly and replaced if necessary.

Rotor and Stator Control: The condition of the rotor and stator parts inside the pump should be examined regularly. If there is wear or damage, it may need to be repaired or replaced.

Electrical Controls: In electric motor pumps, it must be ensured that electrical connections, cables and other electrical components are working properly.

Some of the Pump Types

Pumps are designed in different types according to different usage purposes and needs. Here are some commonly used pump types:

Circular Piston Pumps: These types of pumps are generally used in high pressure applications and have high efficiency.

Diaphragm Pumps:Diaphragm pumps are known as a self-priming type suitable for chemical, food or sensitive applications.

Dry Screw Pumps: These pumps are generally used in industrial applications and stand out with their high efficiency.

Centrifugal Pumps:Centrifugal pumps are a popular type of pump that is widely used to transport water and wastewater and is frequently observed in public water installations.

Spurt Pumps: Spurt pumps are pumps designed to transport non-flammable liquids and manufactured specifically for use in explosive atmospheres/p>

Each type of pump has different advantages and disadvantages and may be more effective in certain applications. When choosing a pump, it is important to choose the right pump type, taking into account specific requirements and performance criteria.